Oil Separator: Active vs. Passive — How It Works, Symptoms of Failure, and When to Service

Oil Separator: Active vs. Passive — How It Works, Symptoms of Failure, and When to Service

The oil separator (also called crankcase ventilation) is one of those engine components that often goes unnoticed — until it fails. Despite its small size, it plays a crucial role in engine durability, system tightness, and emissions control.

In this article, you’ll learn:

-

what the oil separator is and why it matters,

-

the difference between passive and active systems,

-

typical symptoms of a failing separator,

-

when servicing or replacement is necessary,

-

and how to maintain it to avoid costly engine repairs.

What is an oil separator and why is it important?

During engine operation, unburned gases escape past the piston rings into the crankcase, where they mix with oil vapors. Without proper evacuation, crankcase pressure builds up — leading to oil leaks, seal damage, and poor engine performance.

The oil separator regulates this process, routing gases back into the intake system to be burned again. This keeps crankcase pressure stable and reduces harmful emissions.

Passive vs. active oil separator — the differences

While both systems serve the same purpose, they differ in design and precision:

| Feature | Passive oil separator | Active oil separator |

|---|---|---|

| Operation | simple setup with membrane or check valve | electronically controlled / integrated valve |

| Accuracy | less precise flow regulation | adapts actively to driving conditions |

| Application | common in older engines | standard in modern engines |

| Pros | inexpensive, simple, easy to replace | better control, fewer deposits |

| Cons | prone to oil carry-over | more complex and expensive to repair |

Active systems dominate in modern vehicles since they manage crankcase gases more precisely, reducing intake system contamination and turbocharger fouling.

Typical symptoms of a faulty oil separator

When the separator malfunctions, you may notice the following warning signs:

-

Increased oil consumption — oil gets sucked into the intake and burned.

-

Blue exhaust smoke — a classic symptom of oil entering the combustion chamber.

-

Rough idle or misfires — caused by unmetered air entering through a damaged membrane.

-

Oil leaks around the engine — crankcase overpressure forces oil out through seals.

-

Whistling or hissing noises — often from a torn membrane or stuck valve.

-

Power loss and higher fuel consumption — due to disrupted intake balance.

Ignoring these signs can lead to severe consequences: clogged intake manifolds, damaged turbochargers, or even complete engine failure.

How to check the condition yourself

You don’t always need special tools to assess your oil separator:

-

Oil cap test: with the engine idling, remove the oil filler cap. Strong suction or “dancing” movement usually means a faulty separator.

-

Inspect hoses: heavy oil deposits or milky residue (“mayonnaise”) indicate problems.

-

Observe smoke and oil use: blue smoke and sudden oil loss are clear red flags.

-

Diagnostic tools: workshops measure vacuum levels or electronically test valve operation.

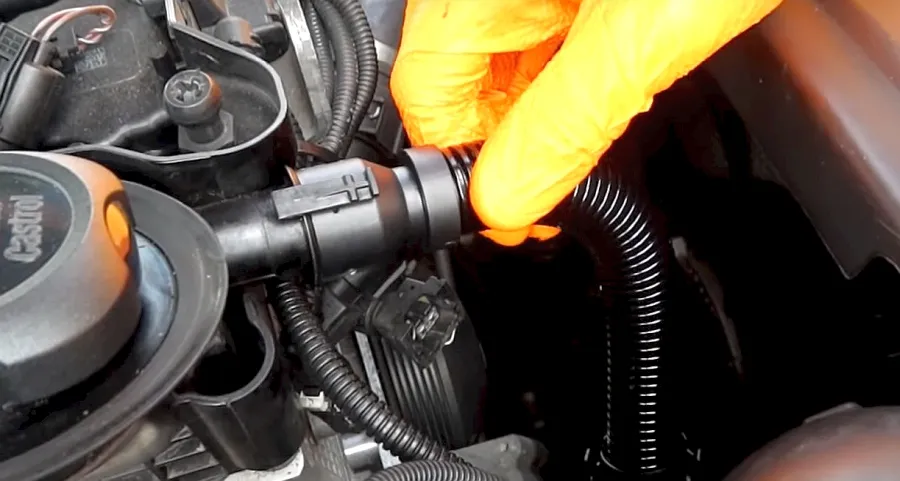

When to service or replace the oil separator

The separator works under harsh conditions — heat, oil mist, and deposits — so wear is inevitable.

-

If you notice smoke, high oil use, or loss of power, get it inspected immediately.

-

In simple passive systems, replacing the valve or membrane may be enough.

-

In modern engines, the separator is often integrated into the valve cover — meaning full module replacement is required.

-

A good rule of thumb: check the separator during major engine service, like timing belt replacement.

Repair and replacement costs

The costs vary depending on vehicle type and system design:

-

Basic systems: $100–$200 for valves or hoses.

-

Complete modules: $200–$400 in parts + $300–$600 labor.

-

Active, integrated systems: $500–$1,200 for parts, with total costs up to $1,500.

Delaying repairs can lead to additional expenses from cleaning intake systems, repairing turbos, or fixing sensors.

Maintenance tips for longer lifespan

-

Change oil and filters regularly — fresh oil reduces foaming and sludge buildup.

-

Use the manufacturer-approved oil — wrong viscosity accelerates wear.

-

Check hoses and seals — replace if brittle or cracked.

-

Avoid frequent short trips — condensation leads to sludge and emulsions.

-

Include separator checks during inspections — a quick workshop test can prevent big issues.

Conclusion

The oil separator may be small, but it’s critical to your engine’s health. Whether passive or active, a faulty separator can cause major problems if ignored. By recognizing symptoms early and maintaining the system properly, you’ll avoid costly repairs and keep your engine running clean and efficient.