CAN Signal in Vehicles — What to Check When Everything Stops Working

CAN Signal in Vehicles — What to Check When Everything Stops Working

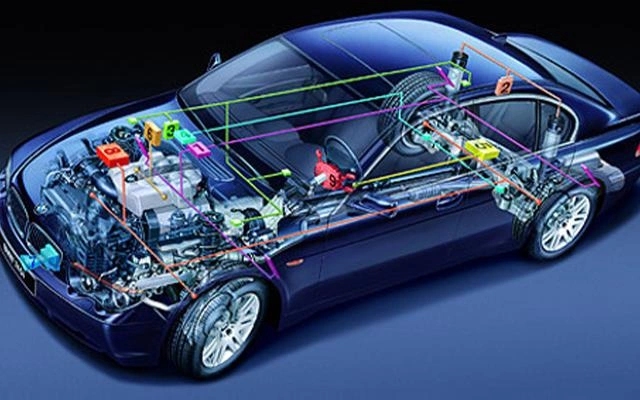

Modern cars rely heavily on the CAN bus (Controller Area Network) — a communication network that connects all electronic controllers and sensors in the vehicle. A failure in this network can immobilize the car and cause many seemingly unrelated systems to stop working at once. Below, I explain how to recognize CAN signal failures, what to check first, and why sometimes the best solution is expert diagnostics.

What is the CAN signal and why is it critical?

The CAN bus is the internal communications network in a vehicle, enabling various electronic modules to exchange data. Instead of running separate wires to each component, modules “talk” over the same network wires.

Through the CAN network, the engine control unit sends data to the dashboard; the ABS module shares wheel speed; safety sensors trigger airbags — even systems like climate control, audio, or power steering often rely on CAN-driven data. Without a functioning CAN bus, many functions fail simultaneously, not just one.

A breakdown in CAN communication often means serious safety and usability issues — this is why fast diagnosis and repair are essential when CAN faults appear.

Symptoms of CAN network failure — what to watch for

CAN problems rarely show up as a single failure. Common signs include:

-

Multiple systems failing at once — e.g. window controls, dashboard display, ABS, power steering.

-

Several warning lights on the instrument cluster simultaneously.

-

Error codes indicating “no communication” or module timeouts.

-

The engine entering limp mode or reduced power mode.

-

In extreme cases — the car won’t start at all.

-

Intermittent failures: displays flickering, audio system cutting out, climate control shutting off occasionally.

-

Failures tending to worsen with vibrations, moisture, or higher temperatures.

These symptoms often appear together and make troubleshooting more complex.

Common causes of CAN communication problems

CAN network breakdowns rarely happen randomly. Typical root causes include:

-

Damaged wiring and harnesses — insulation wear, cut or pinched cables, broken shielding.

-

Corroded connectors and pins, especially in older cars: corrosion disrupts data signals.

-

Faulty ECU/module — a defective or “hung” control module can disrupt the entire bus.

-

Aftermarket or poorly connected devices — alarm systems, GPS trackers, or DIY modifications improperly connected can overload or short the network.

-

Environmental factors — moisture, vibrations, temperature extremes cause micro-cracks, loose solder, or wire fractures over time.

Because the CAN bus is so integral, even a small fault in one area can propagate and disrupt many systems.

What to check first when CAN fails

When the CAN network fails, a structured diagnostic sequence helps isolate the issue:

-

Fuses and power supply

A module losing power can cascade into network-wide failures. Always begin by checking fuses and voltage supply to modules. -

Connectors and wiring harnesses

Inspect wiring especially near areas exposed to vibration or moisture (engine bay, door sills). Look for loose, dirty, or corroded pins and plugs. -

CAN high / CAN low lines resistance

Measure the resistance between CAN High and CAN Low. A typical value is about 60 Ω (if two 120 Ω termination resistors are present). Deviations can indicate failed termination resistors or wiring shorts. -

ECU/module communication

If wiring checks out, suspect a failed control module. Use a diagnostic interface to see which modules respond and detect “dead” devices. -

Use diagnostic tools

A regular multimeter may help with basic checks, but resolving complex CAN issues often requires tools like:-

OBD-II interface / scan tool

-

Oscilloscope — to view signal waveforms on CAN lines

-

Specialized CAN testers — for simulating signals, module isolation, and network tracing

-

Starting from these basics helps narrow down the fault quickly and avoid wasted effort.

Common mistakes when repairing CAN networks

Some typical missteps worsen the issue:

-

Swapping control modules prematurely — the root cause often lies in wiring or connectors, not the module.

-

Poor wiring repairs — twisting wires or using non-shielded connectors can disrupt signal integrity.

-

Neglecting basic measurements — relying solely on scan tool errors without checking physical wiring or resistance.

-

Adding electrical devices improperly — installing accessories (alarms, GPS, media systems) without considering CAN loading or proper interfacing.

-

Disconnecting modules to restore partial function — removing a faulty module might temporarily restore partial communication, but it’s a band-aid, not a real fix.

Smart, methodical diagnostics avoid these pitfalls.

Can you fix CAN yourself or should you go to a shop?

The CAN network is complex and every module and wire matters. While you can check basics — visual inspection, fuses, connectors — full diagnosis often requires advanced tools. In many cases, professional electronic/mechatronic shops are better equipped to methodically trace and restore CAN.

If you’re confident in electronics and have the right tools (oscilloscope, CAN testers), you might resolve some issues on your own. But if the network is badly disrupted or a module is replaced, it’s safer to rely on skilled specialists.

How to prevent future CAN failures

You can’t eliminate all risk, but good preventive practices help:

-

Regular inspections of wiring and connectors, especially in areas exposed to dirt, moisture, and salt (door sills, engine bay, underbody).

-

Avoid non-professional electrical modifications — always install accessories in a way that respects CAN integrity.

-

Protect against moisture and corrosion — wash the undercarriage, use dielectric grease in connectors, and store the vehicle away from harsh environmental exposure.

-

Periodic diagnostic checks — even when no symptoms appear, scanning modules for communication errors can catch problems early.

With careful maintenance, it’s possible for the CAN network to function reliably for many years, minimizing the risk of sudden failures.